Lifting slings are critical components in countless industries, from construction and manufacturing to logistics and recovery.

They serve as the flexible link between a lifting device (like a crane, hoist and the load being moved.

Factors to consider with Slings and Rigging

1. Load Weight and Center of Gravity:

The total weight must be known to ensure the sling's Working Load Limit (WLL) is not exceeded.

The WLL is the maximum safe load the sling can bear.

The sling must be positioned accurately relative to the load's center of gravity to prevent tilting.

2. Hitch Type:

The way the sling is attached to the load (hitch configuration) significantly affects the sling's WLL.

Understanding Hitch Configurations

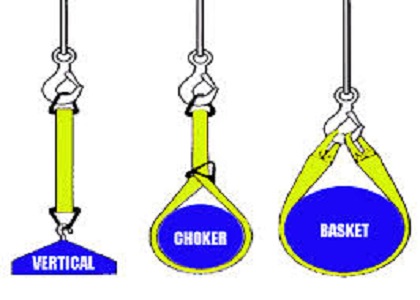

The most common ways to rig a sling are:

Hitch Type

Description

Effect on WLL

Notes

Vertical Hitch

Sling is attached vertically to a load fitting (like an eyebolt)

100% of the stated WLL.

Offers no control over load rotation.

Basket Hitch

Sling cradles the load, with both ends attached to the hook

Can be up to 200% of the vertical WLL (if parallel and load is balanced).|

Excellent for cradling long objects. Requires proper balance to prevent slipping.

Choker Hitch

Sling passes around the load and through one of its own eyes/ends to form a noose

Reduces WLL (typically to 80% )

Excellent grip and control, used for turning loads. The choke point should be on the sling body, not the eye.

3. ⚠️ Sling Angle:

In a multi-leg sling, as the angle between the sling legs and the vertical increases, the tension on each leg also increases dramatically.

A small change in angle can lead to a significant overload. Always aim for the largest possible angle to the vertical (closest to 90 degrees).

Never exceed the Working Load Limit (WLL) marked on the sling's tag.

Account for the load weight, hitch configuration, and angle of lift

By understanding the fundamental principles, you can ensure your lifting operations are carried out safely and effectively